Why you should connect your Modbus Devices to Sensor-Online Platform

In today’s interconnected world, linking many devices to the digital realm is invaluable. Modbus technology, a mainstay in industrial automation and smart home technology, is pivotal in this connectivity. This tutorial will explore connecting a Modbus device to the Sensor-Online platform. Sensor-Online, a cloud-based IoT platform, offers a comprehensive suite of functionalities tailored to the management and integration of IoT devices. By interfacing your Modbus device with Sensor-Online, you gain access to numerous benefits:

- Centralized IoT device management.

- Robust data collection and secure storage.

- Real-time monitoring and timely alerting.

- Remote device administration and configuration.

- Seamless integration with other IoT devices and applications.

Unveiling Modbus

The Modbus communication protocol is a venerable stalwart in networking technologies. Over time, it has continued to dominate many applications, including industrial automation, process control, building automation, transportation, energy management, and remote monitoring.

Modbus is omnipresent in various sensor and controller devices, including programmable logic controllers (PLCs), process controllers, sensors for process monitoring, motor drives, energy meters, SCADA systems, and many other embedded devices. Initially designed for communication between PLCs and computers, Modbus has evolved into a universally accepted communication protocol, seamlessly interconnecting diverse industrial electronic devices.

Modbus: A Glimpse into Technical Nuances

Transport Layers of Modbus

Modbus employs various transport layers, including RS-232, RS-485, and Ethernet, each tailored to specific requirements. Occasionally, RS-422 is also used. Among these, RS-232, recognized as the standard computer COM or serial port, stands out. Modern implementations commonly use 9-pin D-sub type connectors (DB9).

RS-485, a successor to RS-232, offers two distinctive features: the ability to communicate with multiple destination devices (up to 32, extendable to 256 with fractional-load transceivers) and superior resistance to electrical noise interference. RS-485 uses a pair of wires for signal transmission, ensuring even impact from external interference.

Modbus communication over Ethernet, known as Modbus TCP, represents a significant advancement. Ethernet’s high bandwidth supports transmitting more messages and allows thousands of connected devices, surpassing RS-485’s limitation. Unlike RS-485, Modbus TCP also supports multiple clients simultaneously.

The choice of transport method is secondary to connecting to the Sensor-Online platform. If you have any queries or need assistance with device linkage, don’t hesitate to contact us. Information on how to do so can be found here.

Security Concerns in the Modbus Protocol

Modbus is notorious for its lack of security features. Whether Modbus RTU or Modbus TCP, the protocol offers no inherent security measures such as passwords, authorizations, or encryption. Relying solely on firewall protection is insufficient, as it only relocates the vulnerability to any server authorized to access the controller.

Modbus RTU vs. Modbus TCP

The primary distinction between Modbus RTU and Modbus TCP (Modbus IP or Modbus TCP/IP) lies in their physical layers. Modbus TCP uses Ethernet, while Modbus RTU is tailored for serial communication. Modbus TCP’s 6-byte header facilitates routing and CRC validation, allowing multiple clients to efficiently connect and utilize Ethernet bandwidth.

In a Modbus RTU setup, a single client (Modbus master) communicates with server devices (Modbus slaves) simultaneously. In contrast, Modbus TCP supports multiple clients, enhancing flexibility and efficiency. However, Modbus TCP requires network switches, while Modbus RTU can daisy-chain devices.

Modbus RTU vs. Modbus ASCII

Serial Modbus connections offer two transmission modes: ASCII and RTU. ASCII messages are human-readable, while RTU messages are encoded in binary. RTU’s compact messages enable higher data exchange rates. All nodes in a Modbus network must use the same transmission mode, as Modbus ASCII and Modbus RTU are incompatible.

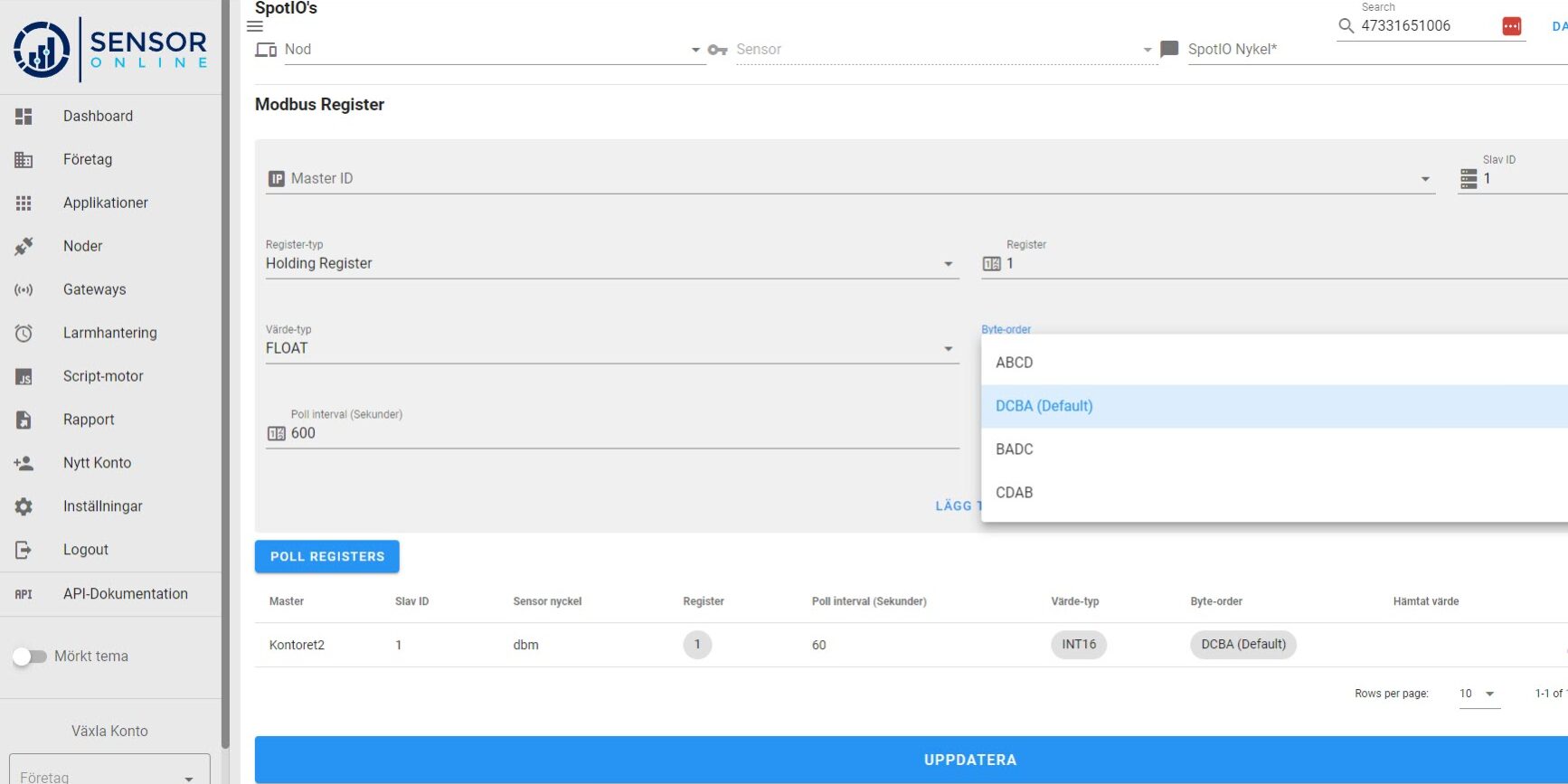

Connecting Modbus Devices to Sensor-Online

To connect your Modbus device to the Sensor-Online platform, follow these steps:

- Prepare Your Modbus Device: Ensure your Modbus device is configured correctly and operational.

- Set Up Sensor-Online:

- Create an account on Sensor-Online and log in.

- Navigate to the device management section and add a new Modbus device.

- Configure Network Settings:

- For Modbus TCP: Configure your device’s network settings to communicate with the Sensor-Online server.

- For Modbus RTU: Connect your device to a Modbus RTU and the TCP gateway if needed.

- Link the Device:

- Enter the device details, including its IP address (for Modbus TCP) or COM port (for Modbus RTU).

- Set the correct baud rate, parity, and other communication parameters.

- Test the Connection:

- Use Sensor-Online’s tools to test the connection.

- Verify data transmission and ensure the device is correctly reporting to the platform.

- Monitor and Manage:

- Utilize Sensor-Online’s dashboard to monitor real-time data.

- Set up alerts and configure device settings as required.

Conclusion

Connecting Modbus devices to the Sensor-Online platform unlocks the potential of IoT in your operations. With centralized management, robust data collection, and real-time monitoring, Sensor-Online offers a powerful solution for integrating and optimizing your IoT infrastructure. Embrace the future of connectivity and experience the benefits of seamless device integration with Sensor-Online.