Harnessing the Power of IIoT with Sensor-Online IoT Portal

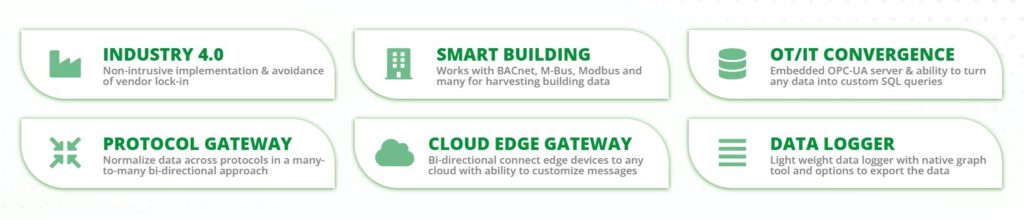

The Sensor-Online IoT portal is a comprehensive solution that integrates various industrial devices seamlessly, ensuring rapid, reliable, and secure access to critical data from industrial processes and embedded systems. By leveraging this platform, engineers and managers can gain real-time insights in various formats, such as databases, spreadsheets, or web pages, enabling informed decision-making and enhanced operational efficiency in the Industrial Internet of Things (IIoT) context.

With robust features like data networking, historical data storage, and redundancy support, the Sensor-Online IoT portal meets the diverse needs of modern industrial environments. Its versatile scripting language and free API provide the adaptability required for any real-time data connectivity requirement, making it an indispensable tool for navigating the complexities of IIoT and driving digital transformation.

Simplify Your Industrial Digitization Journey

Sensor-Online simplifies your industrial digitization journey by enabling easy connection of any PLC and protocol within minutes and allowing for cloud-based asset monitoring. Reach out to learn more and start transforming your operations today.

The Industrial Internet of Things (IIoT): Transforming the Industrial Sector

The Industrial Internet of Things (IIoT) marks a significant transformation in the industrial sector, driven by the integration of advanced technologies like IoT, big data, machine learning, and automation. While IoT primarily targets consumer devices and applications, IIoT is focused on industrial contexts such as manufacturing, logistics, oil and gas, agriculture, and more.

- Definition and Core Concepts: IIoT involves deploying a network of sensors and smart devices integrated into industrial equipment. These sensors collect extensive data on equipment performance, environmental conditions, and operational efficiency. The core concept of IIoT is connecting machines, devices, sensors, and people to facilitate data collection, exchange, and analysis, thereby enhancing industrial processes.

- Data Analytics and Insight: Data analytics is at the heart of IIoT. By analyzing data from sensors and devices, industries gain valuable operational insights. This analysis can reveal patterns, trends, and anomalies, enabling predictive maintenance, optimizing production lines, and improving energy efficiency.

- Predictive Maintenance: One of the most significant applications of IIoT is predictive maintenance. IIoT systems can predict machine failures and proactively schedule maintenance by continuously monitoring equipment conditions. This approach significantly reduces downtime and maintenance costs.

- Enhanced Operational Efficiency: IIoT enhances operational efficiency by enabling real-time monitoring and control of industrial processes. This capability allows immediate adjustments to improve productivity, reduce waste, and enhance quality control.

- Integration with Existing Systems: IIoT often involves integrating new sensors and technologies with legacy equipment, allowing a gradual and cost-effective transition to smarter industrial operations without requiring a complete system overhaul.

- Cybersecurity Concerns: Increased connectivity of industrial systems elevates cybersecurity concerns. Protecting sensitive data and securing connected devices is paramount. IIoT solutions must incorporate robust security protocols to safeguard against cyber threats.

- Impact on the Workforce: IIoT impacts the workforce by necessitating new skills and training. Workers must adapt to more technologically advanced environments, emphasizing digital literacy and data analysis skills.

- Scalability and Flexibility: IIoT solutions are scalable, allowing expansion or reduction based on business needs. This scalability will enable industries to start small and grow their IIoT capabilities as needed.

- Energy Efficiency and Sustainability: IIoT contributes to energy efficiency and sustainability by optimizing processes and reducing waste. Industries can lower energy consumption and carbon footprints, supporting environmental conservation efforts.

- Future Trends and Developments: IIoT is set for further growth, with advancements in AI and machine learning expected to enhance its capabilities. Integrating emerging technologies like 5G and blockchain could unlock new possibilities, driving further innovation in industrial processes.

Key Protocols in the Industrial Internet of Things (IIoT)

In the Industrial Internet of Things (IIoT) realm, numerous protocols play pivotal roles in facilitating communication and data exchange between devices, sensors, and systems. Here are ten important protocols commonly used in IIoT environments:

- MQTT (Message Queuing Telemetry Transport): A lightweight messaging protocol designed for low-bandwidth, high-latency environments. MQTT is widely used in IIoT for efficient data transmission, allowing for effective communication between machines and IoT devices.

- OPC UA (Open Platform Communications Unified Architecture): A platform-independent, service-oriented architecture that integrates all the functionality of the individual OPC Classic specifications into one extensible framework. It’s particularly significant in industrial automation due to its robust security features and interoperability.

- Modbus: An established, simple, and robust protocol used in many industrial electronic devices. It’s often employed for connecting industrial electronic devices and allows for easy data exchange between controllers and sensors or actuators.

- AMQP (Advanced Message Queuing Protocol): A reliable and secure protocol designed for messaging between applications or organizations. AMQP is widely used in IIoT for its flexibility and scalability in complex systems.

- DDS (Data Distribution Service): A middleware protocol and API standard for data-centric connectivity. DDS is designed for high-performance, real-time scalability and is widely used in mission-critical applications in IIoT.

- CoAP (Constrained Application Protocol): A web transfer protocol designed for use with constrained nodes and networks in the IoT. CoAP is particularly suited for simple, low-power devices and can easily translate to HTTP for integration with the web.

- Ethernet/IP: An industrial Ethernet standard used in automation applications. It’s popular in IIoT because it uses familiar Ethernet and TCP/IP technology, making integration with industrial systems easier.

- PROFINET: An industry technical standard for data communication over Industrial Ethernet, designed for collecting data from and controlling equipment in industrial systems.

- Zigbee: A specification for a suite of high-level communication protocols using low-power digital radios. It’s used in IIoT to create personal area networks with small, low-power digital radios, which are ideal for control and sensor networks.

- WirelessHART: A wireless sensor networking technology based on the Highway Addressable Remote Transducer Protocol (HART). It’s designed for process automation applications and is widely used in IIoT for its reliability and security in challenging industrial environments.

Each protocol addresses specific requirements of IIoT systems, such as real-time data exchange, reliability, scalability, and security. The protocol choice depends on the particular needs of the IIoT application, the environment, and the devices involved.

Choosing the Right Protocol for IIoT Success

Selecting the right protocol is crucial for the success of IIoT deployments. Each protocol offers unique advantages and caters to specific aspects of industrial operations, from real-time data exchange and robust security to scalability and seamless integration with existing systems. By understanding and leveraging these protocols, industries can enhance operational efficiency, improve data-driven decision-making, and ensure reliable and secure communication across their IIoT ecosystems.

As the Industrial Internet of Things evolves, staying informed about the latest developments and best practices in IIoT protocols will be vital to maintaining a competitive edge. Embracing the right technologies and protocols will streamline operations and pave the way for future innovations and improvements in industrial processes.

Feel free to contact our team here for more information on implementing these protocols in your IIoT strategy or to explore how our solutions can support your industrial digitization journey. We’re here to help you navigate the complexities of IIoT and achieve your digital transformation goals.